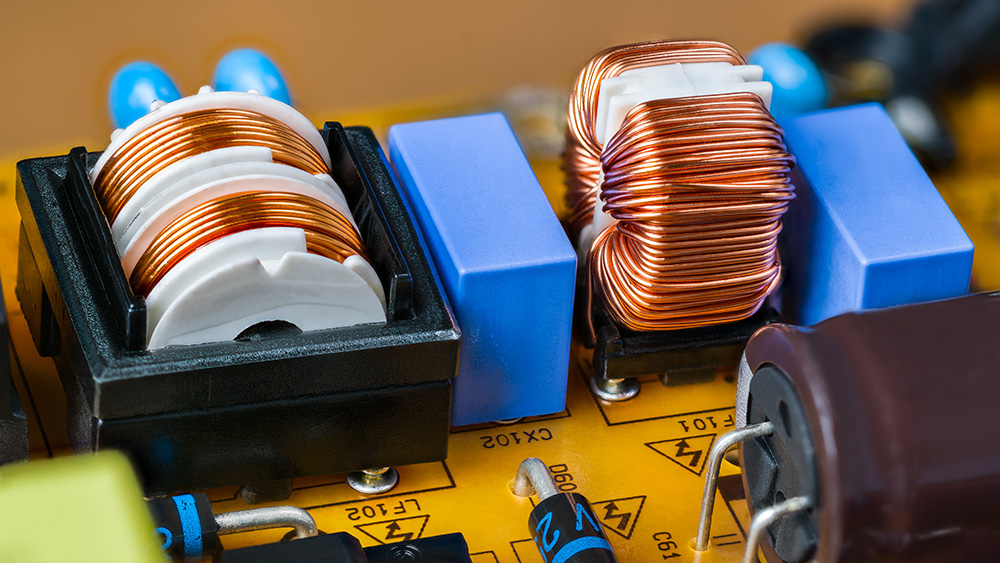

SMPS is a power supply device that uses high-frequency switching technology to convert electrical energy efficiently. Unlike traditional linear power supplies, SMPS converts input power into high-frequency signals, allowing voltage and current levels to be adjusted using transformers or inductors, resulting in highly efficient and stable power output. This design minimizes energy losses typically caused by resistance or transistor voltage drops in linear power supplies.

How SMPS Works

1.Input Rectification and Filtering

Converts AC input power into DC using a rectifier circuit and reduces noise with filtering capacitors.

2.High-Frequency Switching Modulation

High-frequency switching devices (e.g., MOSFETs or IGBTs) convert DC into high-frequency pulse signals, enabling the use of smaller transformers and filters.

3.Energy Transfer and Conversion

The high-frequency signal is adjusted via transformers or inductors to provide the required voltage and power levels.

4.Output Rectification and Filtering

The high-frequency signal is rectified into DC and smoothed using filter circuits to ensure stable output.

5.Feedback Control

Real-time monitoring of output voltage or current adjusts the duty cycle of the switching devices to maintain output stability.

Main Types of SMPS

SMPS can be classified into the following types based on input and output characteristics:

1.DC-DC Converters

Buck Converter: Reduces DC voltage to a lower level.

Boost Converter: Increases DC voltage to a higher level.

Buck-Boost Converter: Combines both buck and boost capabilities.

2.AC-DC Converters

Converts AC power to DC, commonly used in power adapters for consumer electronics.

3.DC-AC Inverters

Converts DC power to AC, widely used in UPS (Uninterruptible Power Supplies) and photovoltaic inverters.

4.AC-AC Converters

Adjusts AC voltage and frequency, commonly used in dimmers or variable frequency drives.

Advantages of SMPS

1.High Efficiency

Since the switching devices operate in either “on” or “off” states, power losses are minimal. Efficiency typically exceeds 80%, with some advanced designs reaching over 95%.

2.Compact Size and Lightweight

High-frequency operation allows for smaller transformers and filters, significantly reducing the size and weight of the device.

3.High Stability

Precise feedback control mechanisms ensure highly stable output voltage and current.

4.Wide Adaptability

Supports a broad input voltage range, making it suitable for global power standards.

5.Versatility

Capable of various power conversion forms, meeting diverse application needs.

Disadvantages of SMPS

1.Electromagnetic Interference (EMI)

High-frequency switching generates EMI, requiring additional shielding and filtering.

2.Complex Design

Compared to linear power supplies, SMPS circuits are more complex and require higher development efforts.

3.Slower Transient Response

During rapid load changes, output voltage may experience brief fluctuations.

Applications of SMPS

1.Consumer Electronics

Used in power adapters for devices such as smartphones, laptops, and televisions.

2.Industrial Automation

Provides stable power for machine control systems and sensors.

3.Communication Equipment

Powers high-efficiency modules in routers, base stations, and other communication devices.

4.Renewable Energy

Used in inverters and voltage regulators for solar power and electric vehicle charging.

5.Aerospace and Defense

Offers high-efficiency, reliable power solutions for satellites, radars, and other critical systems.

Future Trends in SMPS

1.Higher Efficiency and Power Density

The adoption of new materials, such as GaN (Gallium Nitride) and SiC (Silicon Carbide), will significantly improve efficiency and further reduce size.

2.Smart and Digital Control

SMPS integrated with digital signal processors (DSPs) and microcontrollers enables intelligent power management and precise control.

3.Low Power Design

Optimized for IoT and portable devices, SMPS is becoming more energy-efficient to extend device operation times.

4.Environmentally Friendly Solutions

Developing greener, more sustainable power technologies to meet global energy-saving and emission-reduction goals.

Conclusion

SMPS has become an essential part of modern electronic systems due to its efficiency, flexibility, and multifunctionality. Whether in small consumer devices or large industrial systems, SMPS drives technological innovation with its outstanding performance. As advancements in material science and circuit design continue, SMPS will further enhance its efficiency and functionality, powering the future of electronics.