Traditional image sensors use red, green, and blue (RGB) color filters on pixels, but they block a portion of the incoming light, limit camera sensitivity, and limit scaling of the pixel size below ~0.5 microns. Existing color filter technology is reported to waste 70% of light. These issues affect image quality and sensor efficiency.

Smartphone image sensor manufacturers have resorted to increasing the sensor size to capture more light, resulting in larger, bulkier cameras. It is a challenge that requires a different approach, as compact, high-sensitivity image sensors are necessary for slimmer smartphones. It is also becoming a challenge for other applications, such as robotics, augmented reality/virtual reality (AR/VR), and any device where size, power efficiency, and image quality are crucial.

Color-splitting via vertical waveguides

Startup Eyeo, based in Eindhoven, Netherlands, has developed an image sensor architecture—using a proprietary nanophotonic color-splitting technology, originating at research hub imec—that replaces traditional color filters and bucks the trend toward ever-increasing sensor size. Its breakthrough vertical-waveguide-based technology works by splitting light into colors, enabling the sensors to capture and use all incoming light, tripling sensitivity without increasing the sensor size.

The waveguide technology doubles resolution by allowing pixels to receive complete color data. The result is sharp, more detailed images for applications such as computational photography, machine vision, and spatial computing that demand greater precision.

3D rendering of eyeo’s waveguide structure (Source: eyeo)

How it works: The technology captures all photons, compressing them to a size smaller than 0.5 microns. For the first time, photons are not filtered but “guided” to single pixels, delivering maximum light sensitivity and “unprecedented” native color fidelity, even in challenging lighting conditions, according to the company. This translates into image sensors with higher sensitivity, higher resolution, and improved color accuracy.

The single-photon guiding technology breaks resolution barriers, the company said, and enables effective sub-0.5-micron pixels for ultra-compact, high-resolution imaging in extended reality, industrial, security, and mobile applications. This innovation is also fully compatible with existing standard CMOS chip processes with little cost impact.

“The sub-0.5-micron ‘sweet spot’ depends on the application, but it is typically driven by either or both the need for smaller size and higher-pixel resolutions,” said Jeroen Hoet, CEO and co-founder of eyeo. “There is currently a practical limit to effectively go smaller than 1-µm pixels. Below 1-µm pixels, and even above, pixel binning is currently applied to overcome the sensitivity limitations of color filters and microlenses.

“With traditional approaches, the smaller you go in pixel size, the bigger the sensitivity problem becomes,” he continued. “With our solution, we shrink and guide different photons to small pixels, making effective use of single-pixel performance well below current pixel sizes and without a need for pixel binning.”

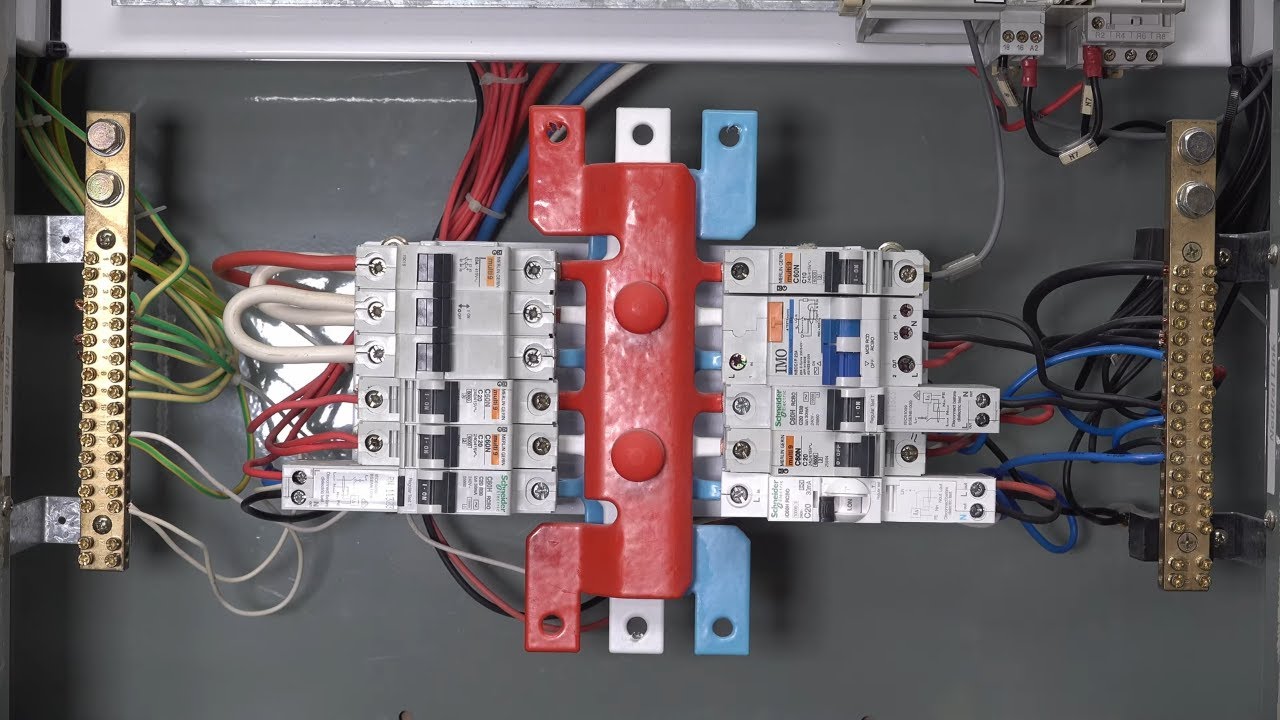

Eyeo color-splitting via vertical waveguides versus tradition color-splitting technology (Source: eyeo)

The fully CMOS-compatible manufacturing process makes the approach scalable and cost-efficient for mass deployment in consumer-grade devices. “Cost reductions include being 3× more efficient in photon collecting so that the sensor size is reduced by 3× compared with existing sensors with similar performance,” Hoet said. “This leads to an immediate cost reduction on the sensor [smaller chips = lower cost] and has a carry-on impact on the size/cost of camera components, including lenses and stabilization MEMS, all of which can also scale down and lead to cost savings.”

Given that the eyeo architecture is fully CMOS-compatible, it eliminates the need for exotic materials or packaging layers. Wafer-level integration also avoids additional packaging complexity. Bypassing the need for larger sensors enables smaller, flatter camera modules, which benefits smartphone and AR/VR designs. The company is integrating photonics in a way that is scalable, manufacturable, and already aligned with industry infrastructure.

Instead of asking fabs to reinvent their process, eyeo provides a path to extend what they already do, with minimal disruption, the company said.

The future

Eyeo has established partnerships with leading image sensor manufacturers and foundries for commercialization. It recently completed a €15 million seed funding, which will be used to improve its current camera sensor designs, further optimize its waveguide technology for production scalability, and accelerate evaluation kit development. The company will also prepare for scale manufacturing of a first sensor product and expand the number of partnerships to bring the technology to market.

Use cases include security and surveillance, where low-light performance is mission-critical; industrial and machine vision, where the elimination of color filter interpolation doubles native color resolution and improves edge clarity; automotive for advanced driver-assistance systems and in-cabin sensing, where 3× light sensitivity improvement and native color capture provide better data quality; and medical imaging, where space and power constraints can be extreme.

Evaluation kits are under development. They are expected to be released in 2026.

The post Startup aims to give cameras perfect eyesight appeared first on Electronic Products.